2BizBox® Manual |

Go back to 11.0 Main |

Tool Management and the Purchasing and Engineering Change Process were introduced in the previous chapters. In this chapter, we will discuss the core modules of the Manufacturing Box: Work Center, Work Instruction, and Time Card.

This chapter focuses on the setup of Work Centers. It is very important to understand the concept and function of the Work Center if you want to successfully implement the manufacturing module of 2BizBox ERP.

The Work Center is the manufacturing resource for production including machines, workers and equipment. A Work Center can be ONE piece of equipment, a group of equipment with the same functions, an automatic production line, a working group, an assembling area, etc. The main purpose of introducing a Work Center into the ERP System is to calculate machine and labor cost. By assigning the Work Center to a Work Instruction and using the Time Card to record work time, precise cost calculation can be achieved.

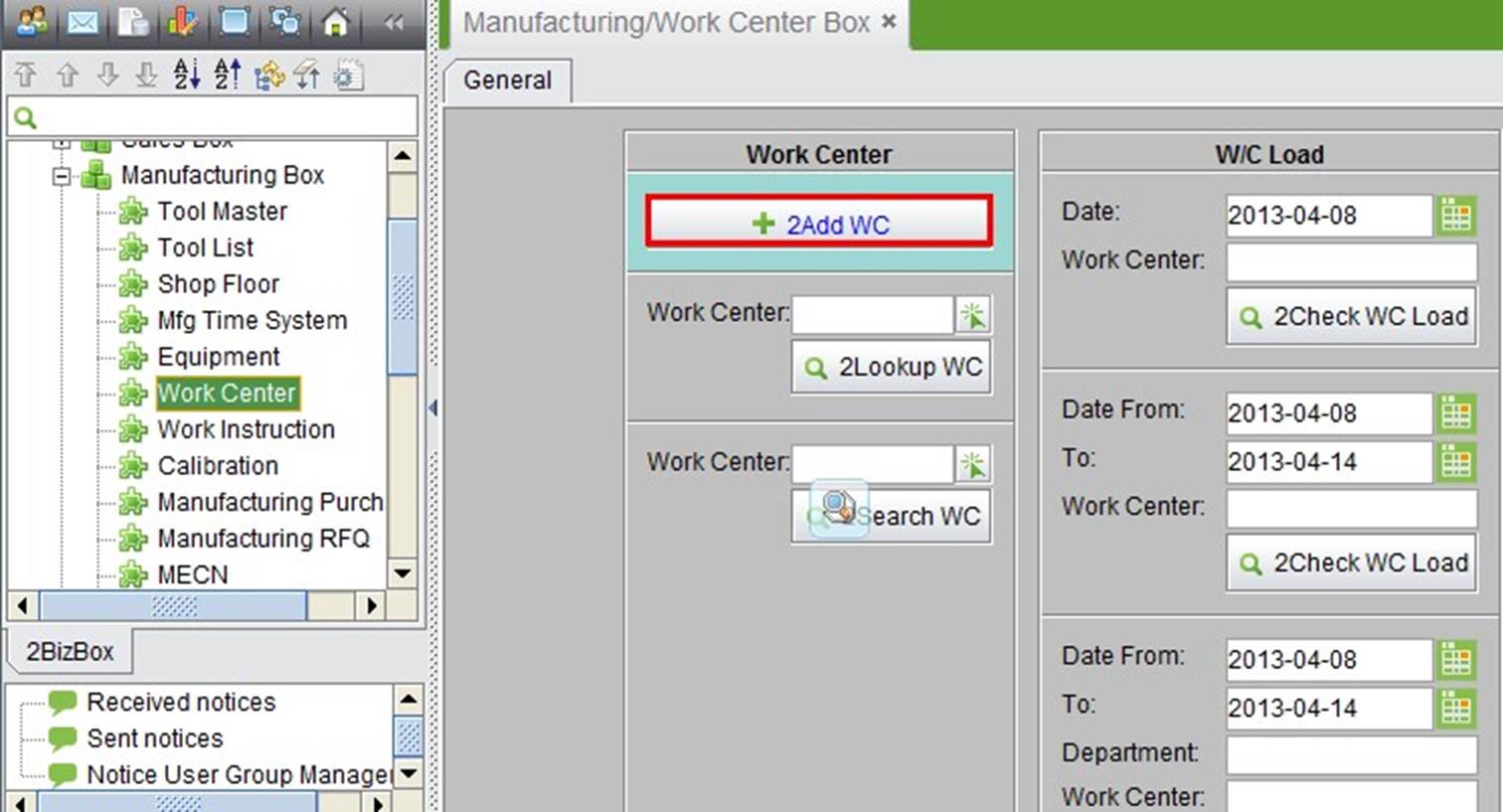

Click “2Add WC” under the “General” tab in “Manufacturing Box – Work Center” to open the adding interface:

|

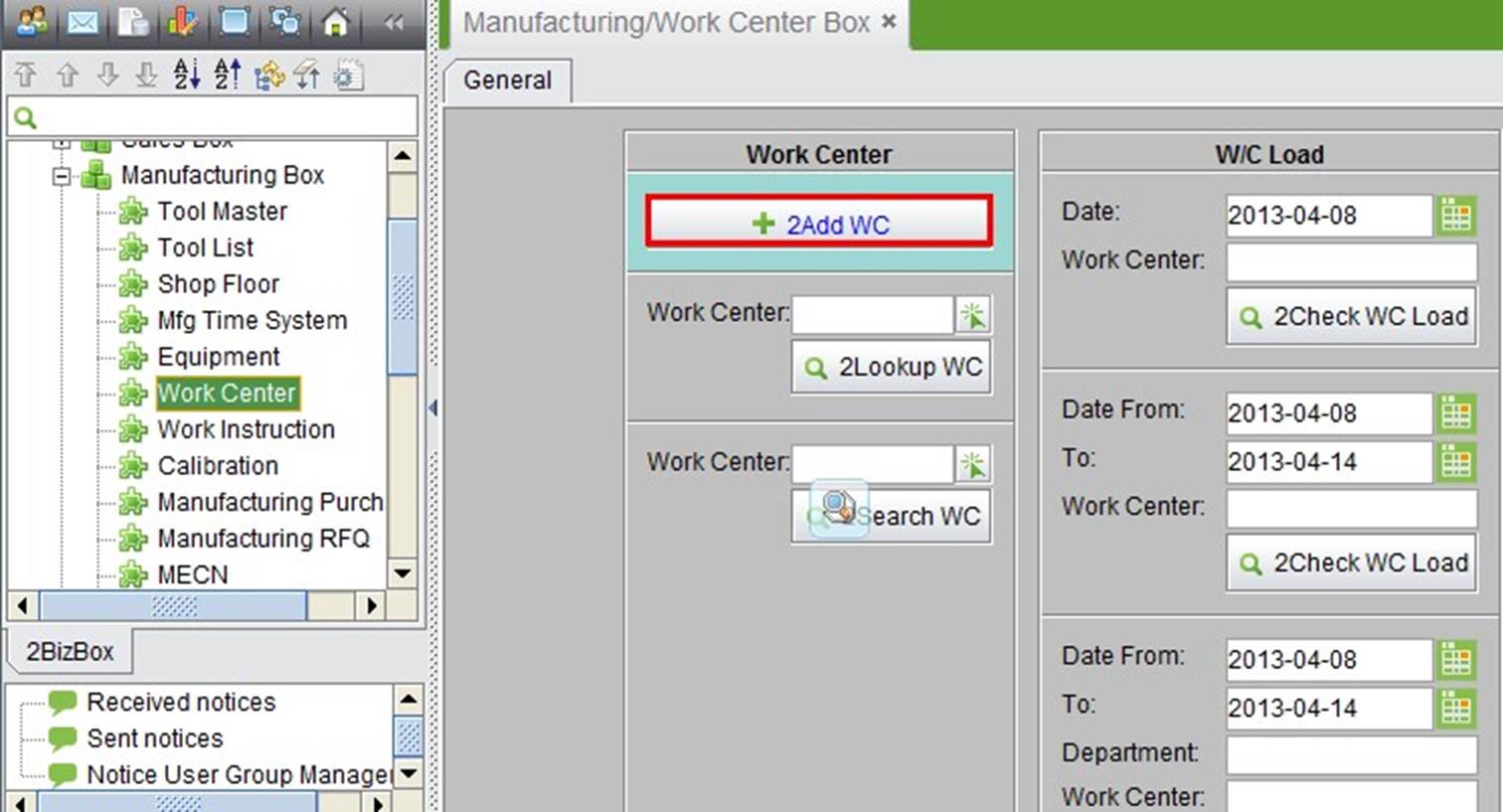

Fill out the WC Number and description and click “2Add:”

|

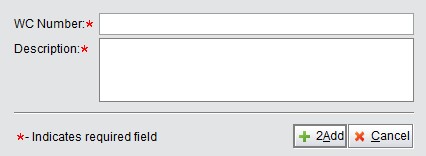

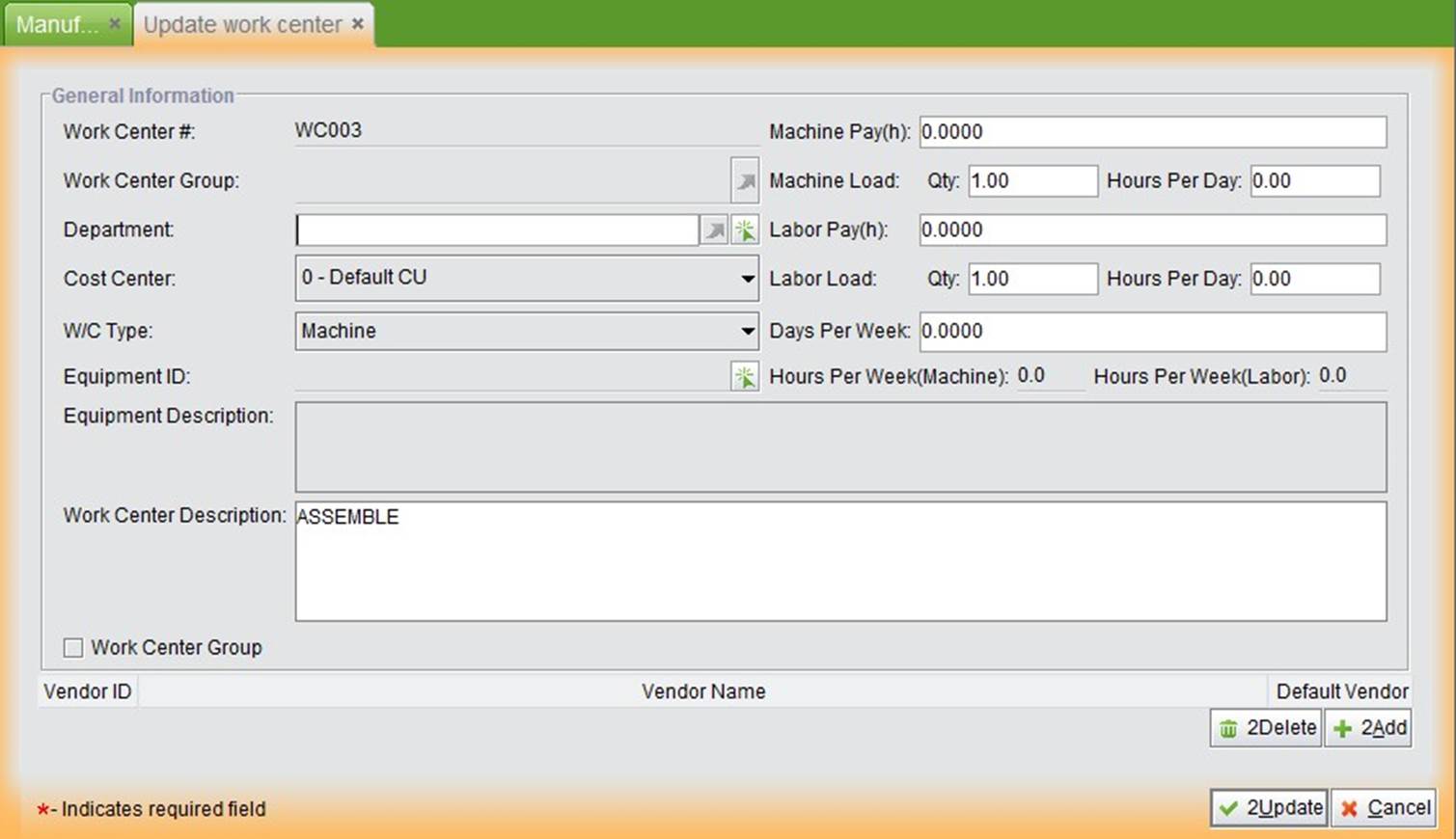

By clicking “2Add,” a new Work Center is created The “Update Work Center” interface will open automatically:

|

Department: Select or fill in the Department that this Work Center belongs to.

Cost Center: Select the Company Unit that this Work Center belongs to.

WC Type: Select the Type for this Work Center. Machine, Labor or Outsourcing.

Equipment ID: If the Equipment of this Work Center is added in the 2BizBox system, you can easily assign it to this WC.

Machine Pay(h): Enter the hourly cost of this Work Center’s machine.

Machine Load: “Qty” is the maximum machine quantity in this Work Center; “Hours Per Day” are the working hours of this machine every day. If there are 4 machines that can work 12 hours per day, then this work center has 48 hours’ of machine workload each day.

Labor Pay(h): Enter the hourly cost of this Work Center’s Labor

Labor Load: “Qty” is the maximum labor quantity in this Work Center; “Hours Per Day” are the working hours of workers every day. If this Work Center allows 2 people to work 8 hours per day, then this Work Center has 16 hours’ of labor workload each day.

Notice: The Machine Load and Labor Load are named “Work Load” for a Work Center. Work Load can be used to check a Work Center’s ability to finish Work Orders. We will introduce how to check Work Load later in this chapter. The WC Type determines the Work Load of a Work Center.

Days Per Week: Open days of this Work Center every week

Hours Per Week (Machine) = “Machine Hours Per Day” * “Days Per Week”

Hours Per Week (Labor)= “Labor Hours Per Day” * “Days Per Week

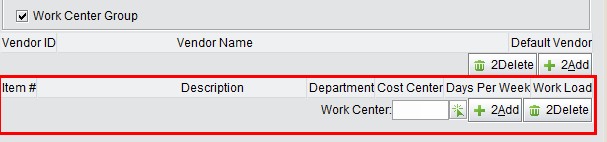

Work Center Group: Check to set this Work Center as a Work Center Group. Work Center Groups will be explained in detail in the next chapter.

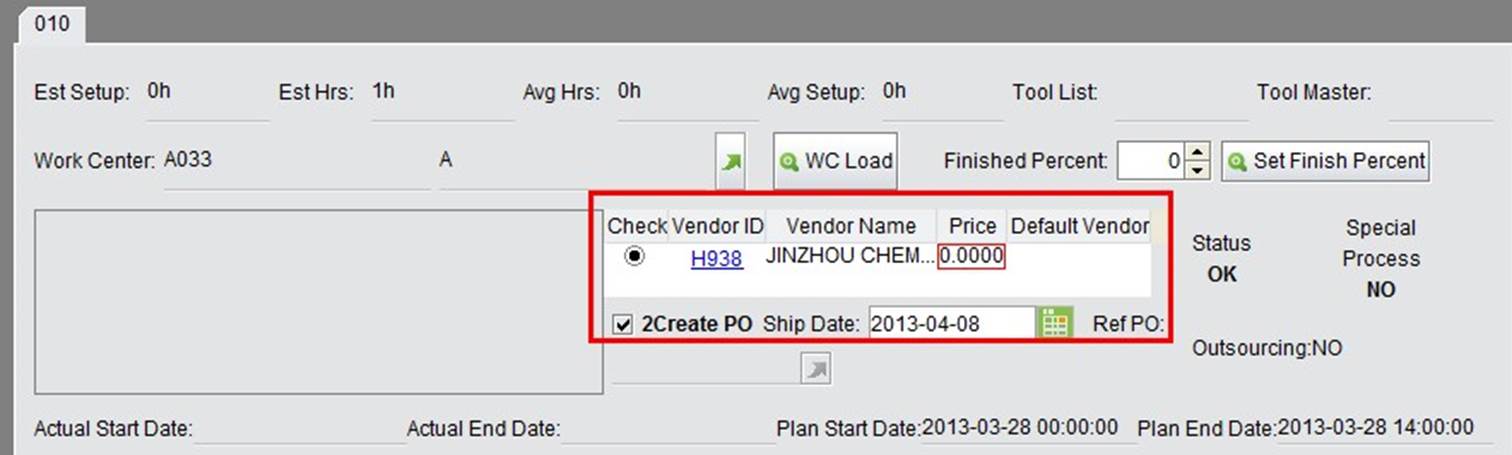

Vendor ID: At the bottom of the interface, you can add a Vendor ID for this Work Center. When a Work

Instruction in a Work Order needs outsourcing, choose a Work Center’s Vendor in the WOWI interface to create a PO.

|

When the Work Center information is set up, click “2Update” to submit the completed form.

In the previous section, we learned that a Work Center could be set as a Work Center Group. A Work Center Group usually contains several Work Centers with the same function.

The adding items will appear when you check “Work Center Group:”

|

Select a Work Center or fill in a WC#. Then click “2Add” to add a Work Center to this Group.

|

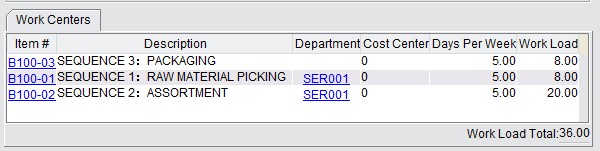

The Work Load Total will show up in the bottom right corner:

|

This is the basic function to look up a Work Center. Fill in the accurate WC# and click this button to open WC Properties.

This is the basic function to search for a Work Center. Fill in the keywords of a WC# and click this button to search for related Work Centers.

The “Check Work Center Load” function provides a direct way to view a Work Center’s load ability for a particular day or a period of time. When a Work Order is approved, the system will calculate the time that each Work Center requires to finish the sequence according to the Work Order’s WOWI (Work Order Work

Instruction) in order to determine whether a Work Center has the ability to finish Work Orders on time. Precise WI, WO and WC data will improve the accuracy of evaluation results.

Here you can check the Work Center Load by day. Select a date and fill in the Work Center you want to check. Click “2Check WC Load” to view the results.

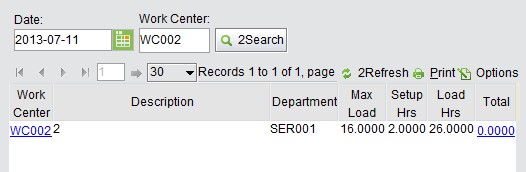

For example, the results of WC Load for WC002 are shown below:

|

In this check function, we assume that all the Work Orders starting from 2013-07-11 must be finished on this day. The max load of WC002 is 16 hours, but we can see from the results that the Setup Hours=2, and the Load Hours=26. Obviously WC002 cannot sufficiently finish the Work Orders.

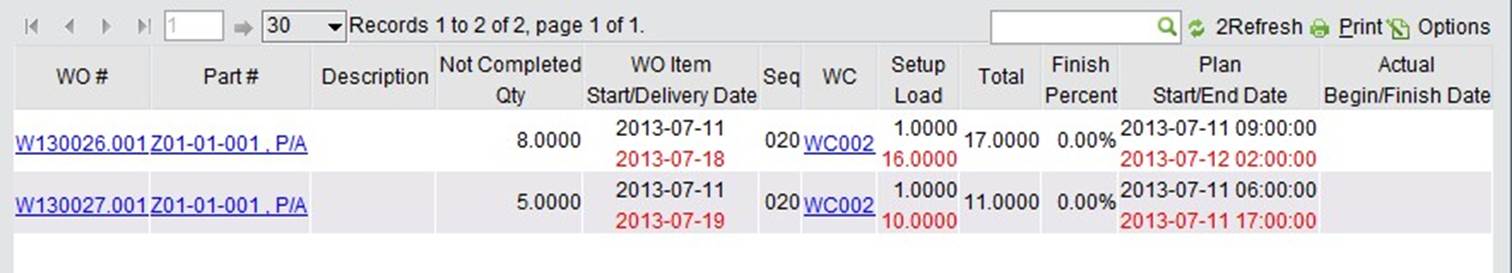

Click “total” to view the details of WC002:

|

There are two tasks arranged for WC002, and the Deliver Dates are 7-18 and 7-19. So the job can be finished later. We can also check the WC Load by period for this Work Center.

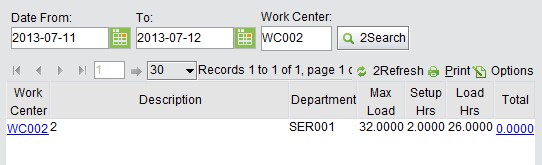

From the above results, we’ve discovered that one day is not enough time to finish all the tasks. So we can check the load by period. Below we see the results of checking WC002 from 07-11 to 07-12:

|

The maximum load for two days is 32 hours, and total hours are 28. So WC002 has the ability to finish the task in this period. And it also has 6 more hours to do other jobs.

This function adds the search condition “Department.” Now you can check WC Load by department when necessary.